If you’re looking for the best 3D printers for product design in 2026, I recommend considering the ELEGOO Centauri Carbon for its high speed and advanced materials support, the FLASHFORGE Adventurer for ease of use and auto leveling, and an upgraded metal spatula for handling complex prints efficiently. These models balance precision, versatility, and reliability. Stay tuned to discover more about top features and how to choose the perfect printer for your needs.

Key Takeaways

- The ELEGOO Centauri Carbon offers high-speed, precise printing with advanced materials and remote monitoring features ideal for professional product design.

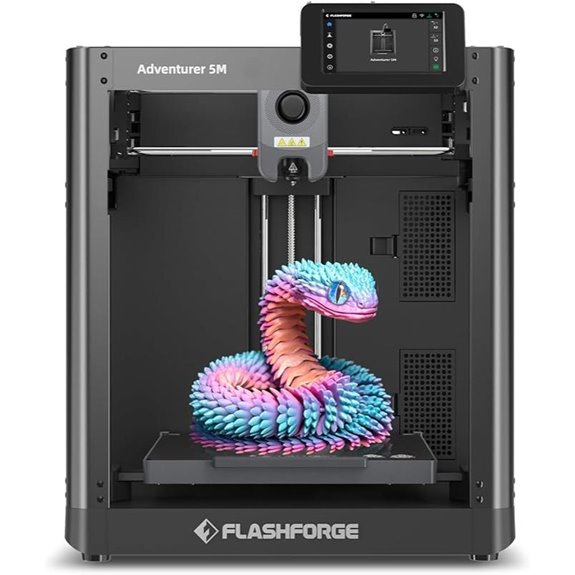

- The FLASHFORGE Adventurer 3 provides automatic bed leveling, large build volume, and quick nozzle swaps, enhancing workflow efficiency.

- Prioritize printers with high resolution (50-100 microns), broad material compatibility, and user-friendly interfaces for detailed product prototypes.

- Reliable support and extended warranties are critical for minimizing downtime during intensive design projects.

- Consider budget options that balance affordability with essential features like speed, precision, and material versatility for ongoing innovation.

| Upgraded Metal 3D Printer Removal Spatula |  | Best Utility Tool | Build Volume: Not specified | Automation: No (manual removal spatula) | Connectivity: Not specified | VIEW LATEST PRICE | See Our Full Breakdown |

| ELEGOO Centauri Carbon 3D Printer with Auto Calibration |  | Best High-Speed Precision | Build Volume: 256x256x256 mm (10”x10”x10”) | Automation: Yes (auto bed leveling) | Connectivity: Remote monitoring via chamber camera and dual LED lighting | VIEW LATEST PRICE | See Our Full Breakdown |

| FLASHFORGE Adventurer 3D Printer with Auto Leveling |  | Best User-Friendly System | Build Volume: 220x220x220 mm | Automation: Yes (auto leveling) | Connectivity: Remote control via Flash Maker app | VIEW LATEST PRICE | See Our Full Breakdown |

| 3D Printing For Dummies |  | Best Educational Resource | Build Volume: Not specified | Automation: Yes (automatic bed leveling) | Connectivity: Remote monitoring and control via mobile app | VIEW LATEST PRICE | See Our Full Breakdown |

| 3D Printing: Scanning Creating Editing Remixing |  | Scanning, Creating, Editing, Remixing: Best Creative Guide | Build Volume: Not specified | Automation: Not applicable (focus on scanning and modeling, not hardware) | Connectivity: Not applicable | VIEW LATEST PRICE | See Our Full Breakdown |

More Details on Our Top Picks

Upgraded Metal 3D Printer Removal Spatula

If you’re working with 3D printers for product design, the Upgraded Metal 3D Printer Removal Spatula is an essential tool that makes removing models easier and safer. Made from polished stainless steel, it’s wear- and scratch-resistant, ensuring durability over time. Its smooth, rounded edge prevents scratches on both models and printer surfaces, while the ergonomic handle with a non-slip sleeve offers a comfortable, secure grip. The 2.3-inch blade provides ample force to handle large or complex prints effortlessly. Plus, with a 2-year warranty and 24/7 support, it’s a reliable addition to your 3D printing toolkit.

- Build Volume:Not specified

- Automation:No (manual removal spatula)

- Connectivity:Not specified

- Material Compatibility:Suitable for various 3D models (implying filament compatibility)

- Speed:Not specified

- User Interface:Ergonomic handle (manual tool)

- Additional Feature:Mirror-polished stainless steel

- Additional Feature:Ergonomic non-slip handle

- Additional Feature:Seamless model peeling design

ELEGOO Centauri Carbon 3D Printer with Auto Calibration

The ELEGOO Centauri Carbon 3D Printer stands out as an excellent choice for professional product designers and serious hobbyists who demand high speed and precision. Its fully assembled, pre-calibrated design means you can start printing right away. The auto bed leveling and intuitive touchscreen make setup effortless, while the rigid die-cast aluminum frame guarantees stability during rapid, detailed prints. Capable of reaching 500 mm/s, it’s built for high-speed production. The enclosed chamber, hotend, and heated bed support advanced materials like carbon fiber composites, producing strong, lightweight parts. Built-in camera and dual LEDs let me monitor prints remotely and create time-lapses with ease.

- Build Volume:256x256x256 mm (10”x10”x10”)

- Automation:Yes (auto bed leveling)

- Connectivity:Remote monitoring via chamber camera and dual LED lighting

- Material Compatibility:Advanced filaments, including carbon fiber reinforced

- Speed:Up to 500 mm/s

- User Interface:Touchscreen controls

- Additional Feature:Auto bed leveling

- Additional Feature:Built-in chamber camera

- Additional Feature:High-speed CoreXY structure

FLASHFORGE Adventurer 3D Printer with Auto Leveling

For product designers seeking precision and ease of use, the FlashForge Adventurer 3D Printer with Auto Leveling stands out as an ideal choice. Its fully automatic bed leveling guarantees flawless first layers without manual adjustments, saving time and reducing errors. The all-metal CoreXY structure provides durability and stability, supporting a 220x220x220mm build volume. With dual-sided PEI platforms, easy removal is a breeze, and quick 3-second nozzle changes improve workflow. The high-flow 32mm³/s nozzle supports efficient printing at speeds up to 600mm/s. Plus, remote monitoring via the Flash Maker app simplifies operation, making it perfect for rapid prototyping and professional use.

- Build Volume:220x220x220 mm

- Automation:Yes (auto leveling)

- Connectivity:Remote control via Flash Maker app

- Material Compatibility:Multiple filament types (implied)

- Speed:Not specified, but high-speed capabilities implied

- User Interface:Touchscreen interface

- Additional Feature:Fully automatic bed leveling

- Additional Feature:Dual-sided PEI platforms

- Additional Feature:Quick 3-second nozzle change

3D Printing For Dummies

Are you new to 3D printing or looking to expand your skills? “3D Printing For Dummies” is a great starting point. It offers an easy-to-understand overview of how digital files become physical objects, highlighting the technology behind it. I find it helpful for learning to design models, select suitable machines and materials, and understand the printing process. The book also covers recent advancements, making it relevant for both beginners and experienced users. It explains industry impacts like rapid prototyping and customization, helping you evaluate if 3D printing fits your needs. Overall, it’s a practical resource to build confidence and stay current in this innovative field.

- Build Volume:Not specified

- Automation:Yes (automatic bed leveling)

- Connectivity:Remote monitoring and control via mobile app

- Material Compatibility:Multiple filament types (implied)

- Speed:Up to 600 mm/s

- User Interface:Mobile app and automatic features

- Additional Feature:Industry application insights

- Additional Feature:Latest technology updates

- Additional Feature:Practical design guidance

3D Printing: Scanning Creating Editing Remixing

If you’re interested in transforming physical objects into digital files or refining existing models, 3D printing offers powerful tools for scanning, creating, editing, and remixing. I’ve seen experts like Frances Le FabShop demonstrate how to digitize real-world items with 3D scanners and improve poor-quality files, ensuring successful prints. Using free software and affordable tech, you can design from scratch or remix existing models—like articulated robots or posable animals—without prior experience. Understanding different 3D printing technologies helps you choose the best equipment for your needs. Mastering these skills opens up endless creative possibilities, making 3D printing an essential part of modern product design.

- Build Volume:Not specified

- Automation:Not applicable (focus on scanning and modeling, not hardware)

- Connectivity:Not applicable

- Material Compatibility:Not applicable

- Speed:Not applicable

- User Interface:Not applicable

- Additional Feature:3D scanning solutions

- Additional Feature:Free design software

- Additional Feature:Source file optimization

Factors to Consider When Choosing 3D Printers for Product Design

When selecting a 3D printer for product design, I consider several key factors to make certain it meets my needs. These include print resolution quality, material compatibility, and build volume size, which directly impact the final product’s precision and versatility. Additionally, I look at speed, ease of calibration, and overall efficiency to make sure the printer fits smoothly into my workflow.

Print Resolution Quality

Choosing a 3D printer with the right print resolution is vital for achieving the detailed and smooth finishes required in product design. Higher resolution means finer detail and better surface quality, which are essential for prototypes and final products. Resolution is usually measured in microns; lower values, like 50-100 microns, indicate higher quality prints. Achieving such detail depends on precise nozzle sizes and stable calibration, so look for machines that offer these features. Keep in mind that finer resolution often increases print time because of the more detailed layer-by-layer process. However, adjustable resolution settings give you the flexibility to balance quality and speed, allowing you to customize your prints based on project needs. Ultimately, selecting a printer with ideal resolution capabilities ensures your designs come out accurately and professionally finished.

Material Compatibility Range

A broad material compatibility range substantially enhances a 3D printer’s versatility, allowing me to create prototypes with various properties—flexible, rigid, or high-temperature resistant. With the ability to print advanced filaments like carbon fiber reinforced or composite materials, my design options expand considerably, enabling the production of more functional and durable parts. The hotend temperature limit is vital; it determines whether I can use materials like ABS, PETG, or nylon without sacrificing quality or risking damage. Compatibility with specialty materials often requires specific extruders, such as all-metal hotends, to handle abrasive or high-temperature filaments effectively. Overall, a versatile material range ensures my printer adapts across industries, from engineering and aerospace to artistic and consumer product design.

Speed and Efficiency

Expanding a 3D printer’s material compatibility range allows me to create a wide variety of prototypes, but speed and efficiency are equally important for effective product design. High-speed printers can reach travel speeds up to 600mm/s, substantially cutting down print times for complex models. Achieving such speeds requires high acceleration rates, like 20,000mm/s², to maintain accuracy during rapid movements. Efficient printers also feature auto bed leveling and quick nozzle swaps, saving setup and troubleshooting time. These capabilities enable me to produce multiple prototypes swiftly, accelerating development cycles and reducing time-to-market. By optimizing print parameters and selecting printers with advanced motion control, I can enhance overall productivity and streamline the design process, ensuring faster iterations and more efficient workflows.

Ease of Calibration

Since calibration impacts print quality and efficiency, it’s essential to take into account how easily a 3D printer can be calibrated when selecting equipment for product design. Automatic bed leveling features make this process straightforward by ensuring the print bed is perfectly aligned without manual adjustments. These auto calibration systems save time, reduce human error, and promote consistent results—crucial factors for frequent users or those producing multiple prototypes. Built-in sensors and software can detect and compensate for bed unevenness during calibration, further streamlining setup. In contrast, manual calibration requires precise adjustments of the bed and nozzle height, which can be time-consuming and prone to inaccuracies. Prioritizing ease of calibration helps maintain productivity and ensures reliable, high-quality prints in a fast-paced design environment.

Build Volume Size

When choosing a 3D printer for product design, considering the build volume size is essential to guarantee it meets your project needs. A larger build volume lets you print bigger prototypes or multiple parts simultaneously, boosting efficiency. It also determines the maximum size of your products without needing to split or assemble components. Your choice depends on your project scale—smaller, detailed parts or larger structural pieces. Keep in mind, bigger build volumes often require a sturdier, more stable frame to maintain precision during large prints. Conversely, smaller build volumes are typically more cost-effective and better suited for intricate, detailed designs. Balancing your project’s size requirements with your budget and printer stability is vital for ideal results.

User Interface Simplicity

A user-friendly interface is essential when selecting a 3D printer for product design because it directly impacts how easily you can operate the machine and achieve consistent results. An intuitive interface with touchscreen displays and simple menu navigation allows for quick adjustments and real-time monitoring, even without technical expertise. Clear visual prompts and minimal button presses streamline the printing process, saving time and reducing errors. Compatibility with mobile apps or remote management tools lets you oversee prints from any device, increasing flexibility. Automated features like auto bed leveling and preset profiles simplify setup and help guarantee consistent quality, especially for complex designs. Overall, a straightforward interface enhances productivity and confidence, making it an invaluable factor in choosing the right 3D printer for your work.

Support and Warranty

Choosing a 3D printer for product design means considering how well the manufacturer supports your ongoing needs. A solid support and warranty plan guarantees quick assistance and repairs, reducing downtime during critical projects. I recommend looking for manufacturers offering at least a 1- to 2-year warranty to cover hardware or software issues. Having 24/7 customer service can save you from delays caused by technical problems, allowing you to troubleshoot or get help whenever needed. Extended support options or on-site service are especially valuable for complex or high-volume printers in professional settings. Clear warranty terms, including what’s covered and how to get repairs or replacements, safeguard your investment and give peace of mind as you focus on your product design work.

Price and Budget

Setting a realistic budget is essential when selecting a 3D printer for product design, as it influences both initial investment and ongoing expenses. Consider the complexity and size of your prototypes to determine an appropriate budget. Higher-priced printers usually provide better precision, larger build volumes, and advanced features ideal for professional work. Conversely, budget options can suit hobbyists or small-scale projects but may have limitations in speed, accuracy, or material compatibility. It’s also important to evaluate the total cost of ownership, including maintenance, replacement parts, and software. Investing in a more reliable, expensive printer upfront can reduce repair needs and upgrades, saving money in the long run. Balancing features with your budget ensures you choose a printer that meets your design needs without overspending.

Frequently Asked Questions

Which 3D Printer Offers the Fastest Print Speeds for Prototypes?

The 3D printer with the fastest print speeds for prototypes is the SprintRay Pro. I’ve found it to be impressive, especially because it balances speed with precision. Its advanced resin technology allows me to produce high-quality prototypes quickly, saving me valuable time. If speed is your priority, this printer is a top choice, offering rapid turnaround times without sacrificing detail or accuracy.

How Do Different Materials Affect the Durability of 3D Printed Products?

Materials matter immensely when it comes to durability in 3D printing. I’ve found that robust materials like ABS and PETG deliver strength and resilience, making products tougher and long-lasting. In contrast, PLA is softer and more prone to cracking under stress. Choosing the right material depends on your project’s purpose—flexible, durable, or biodegradable. I always recommend testing different options to find what best fits your product’s needs.

What Software Is Compatible With the Latest 3D Printers?

The latest 3D printers are compatible with a variety of software like Cura, Simplify3D, and PrusaSlicer, which are user-friendly and offer advanced features. I love using these because they integrate seamlessly with most hardware, providing precise control over print settings. Some printers also support CAD programs like Fusion 360 and SolidWorks, allowing me to directly import my designs for smooth, efficient printing.

How Energy-Efficient Are These Advanced 3D Printers?

Did you know that some of the latest 3D printers use up to 50% less energy than older models? I’ve found that these advanced printers are surprisingly energy-efficient, thanks to innovations like improved heating elements and smarter power management. They often feature auto-shutdown modes and energy-saving settings, which help reduce electricity consumption. Overall, these printers are designed to be eco-friendly, making them a smart choice for sustainable product design.

What Are the Maintenance Requirements for High-End 3D Printers?

High-end 3D printers require regular maintenance to stay in top shape. I clean the print bed and nozzles weekly, check for filament clogs, and lubricate moving parts monthly. Firmware updates are essential for maximum performance, and I calibrate the printer regularly to guarantee precision. Replacing worn-out parts like nozzles or belts every few months keeps the machine running smoothly. Staying proactive with maintenance extends the printer’s lifespan and print quality.

Conclusion

If you’re serious about mastering product design, these 3D printers are game-changers. Whether you want precision, speed, or ease of use, I guarantee one of these will elevate your creative process to legendary status. Don’t settle for anything less—these machines are like having a magic wand in your workshop. Immerse yourself, experiment, and watch your ideas come to life faster than you ever imagined possible!