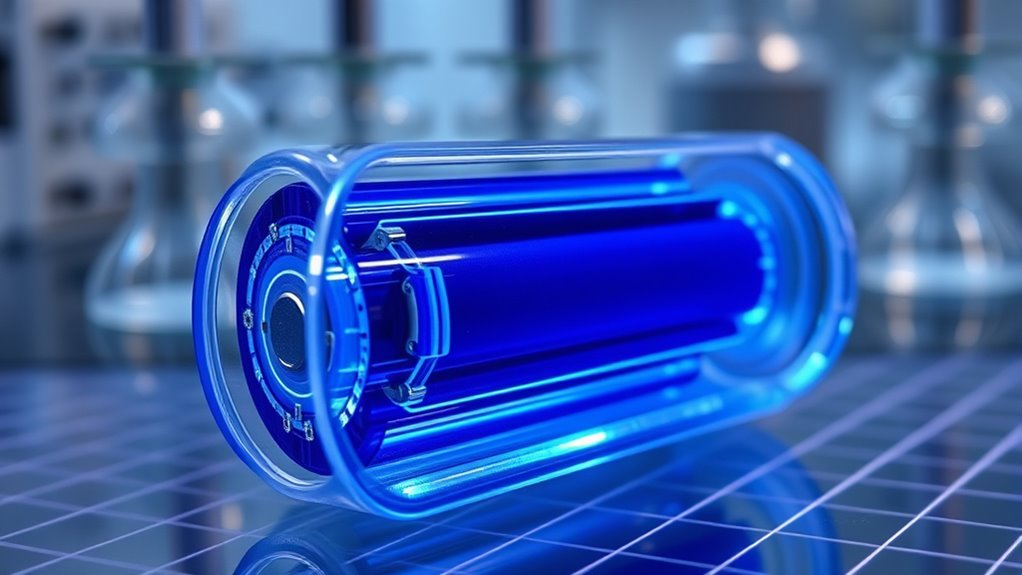

Solid-state batteries are poised to revolutionize energy storage by replacing liquid electrolytes with solid materials, making them safer, more durable, and offering higher energy density. They can charge faster, last longer, and reduce risks like leakage or fire. However, manufacturing challenges like material stability and scaling up production still need solutions. Staying informed will reveal how ongoing innovations are making these next-generation batteries more viable for everyday use.

Key Takeaways

- Solid-state batteries use solid electrolytes, offering increased safety and higher energy density over traditional liquid-based batteries.

- They provide longer lifespan and improved stability, making them suitable for reliable, long-lasting energy storage applications.

- Manufacturing challenges include ensuring high-quality, defect-free electrolytes and seamless electrode interfaces at scale.

- Scalability concerns stem from sensitivity to environmental conditions and complex production processes, affecting mass adoption.

- Advances in materials and fabrication techniques are driving the development of next-generation, safer, more efficient energy storage solutions.

Solid-state batteries are an innovative energy storage technology that promises to revolutionize how we power devices and vehicles. Unlike traditional lithium-ion batteries that rely on liquid electrolytes, these batteries use solid electrolytes, which can greatly enhance safety, energy density, and lifespan. As you explore this technology, you’ll find that electrolyte stability is a critical factor. The solid electrolytes must maintain their structural integrity under various conditions, resisting degradation over time. Achieving this stability isn’t easy—many solid electrolytes tend to be brittle or react with other components, reducing their effectiveness. Overcoming these challenges requires meticulous material engineering, but once perfected, electrolyte stability can lead to batteries that last longer, charge faster, and operate more reliably.

Solid-state batteries offer safer, longer-lasting energy storage through stable, resilient solid electrolytes.

Nevertheless, bringing solid-state batteries from lab prototypes to real-world applications involves significant manufacturing challenges. Producing these batteries at scale demands precise control over material quality and interfaces. For instance, ensuring a seamless contact between the solid electrolyte and electrodes is crucial for efficient ion transfer. Any imperfections or inconsistencies can cause internal resistance or even failure of the cell. Manufacturing processes must consequently evolve to accommodate new materials and complex assembly techniques, which can be costly and time-consuming. Additionally, current manufacturing methods often struggle to produce uniform, defect-free solid electrolytes on a large scale, creating hurdles for commercial adoption. Manufacturing complexity is a key obstacle that industry efforts are actively seeking to address.

These manufacturing challenges also stem from the delicate nature of solid electrolytes. Many are sensitive to moisture and temperature during production, requiring specialized environments that increase costs. Furthermore, scaling up production involves integrating new techniques that might not yet be mature or widely available. This makes the shift from small-scale prototypes to mass production a significant hurdle, delaying the widespread deployment of solid-state batteries. Yet, despite these obstacles, many industry leaders are investing heavily in research and development, aiming to refine manufacturing processes. Innovations such as tape casting, sintering, and advanced coating techniques show promise in overcoming current limitations.

In essence, while electrolyte stability and manufacturing challenges present hurdles, they also highlight the areas where focused efforts can lead to breakthroughs. As advancements are made, you’ll see more reliable, safer, and higher-capacity solid-state batteries entering the market. These improvements will pave the way for electric vehicles with longer ranges, portable electronics with extended battery life, and new energy storage solutions that are safer and more efficient. The journey toward commercializing solid-state batteries is ongoing, but with continued innovation, these challenges are likely to be surmounted, bringing the next generation of energy storage closer to reality.

Frequently Asked Questions

How Long Do Solid-State Batteries Typically Last?

You can expect solid‑state batteries to last around 10 to 15 years, depending on usage and care. Their battery lifespan is generally longer than traditional lithium-ion batteries because they degrade more slowly. Factors like temperature, charging cycles, and storage conditions influence degradation factors, impacting overall longevity. Proper handling and avoiding extreme conditions can help maximize their lifespan, ensuring reliable performance over many years.

Are Solid-State Batteries More Cost-Effective Than Traditional Lithium-Ion?

You might think solid-state batteries are pricier, but their cost comparison to traditional lithium-ion batteries is improving. Although manufacturing costs are higher now, they offer longer lifespan and enhanced safety, which can offset initial expenses over time. As production scales up and technology advances, expect these batteries to become more cost-effective, making them a smarter investment for future applications.

What Are the Main Challenges in Commercializing Solid-State Batteries?

You’ll face main challenges in commercializing solid-state batteries, mainly scalability issues and manufacturing complexities. Scaling up production while maintaining quality proves difficult because current manufacturing processes are costly and intricate. Additionally, ensuring consistent performance and safety across large batches requires advanced techniques and materials. Overcoming these hurdles is essential for making solid-state batteries viable for widespread use, but ongoing research aims to address these obstacles effectively.

Can Solid-State Batteries Be Recycled Easily?

You might wonder if solid-state batteries are easy to recycle. Recycling methods for these batteries are still developing, but material recovery can be challenging due to their complex components. Unlike traditional batteries, you need specialized processes to efficiently extract valuable materials. While progress is being made, current recycling techniques are not as straightforward, and improving material recovery is essential for making solid-state batteries more environmentally friendly and easier to recycle in the future.

How Safe Are Solid-State Batteries in Extreme Conditions?

You’ll find solid-state batteries are highly safe in extreme conditions, thanks to their superior thermal stability. Unlike traditional lithium-ion batteries, they resist overheating or combustion even at high temperatures, maintaining structural integrity. Studies show they can operate safely within a temperature range of -40°C to 150°C. This robustness minimizes risks of fires or failures, making them ideal for demanding environments like aerospace or electric vehicles, where safety is critical.

Conclusion

As you explore the future of energy storage, solid-state batteries shine like a beacon in the dark, promising safer, more efficient power sources. Their potential to revolutionize everything from smartphones to electric vehicles is immense, acting as the catalyst that could spark a new era of innovation. Embracing this technology is like holding a key to a brighter, more sustainable tomorrow—unlocking possibilities that once seemed out of reach.